- Introduction

Introduction

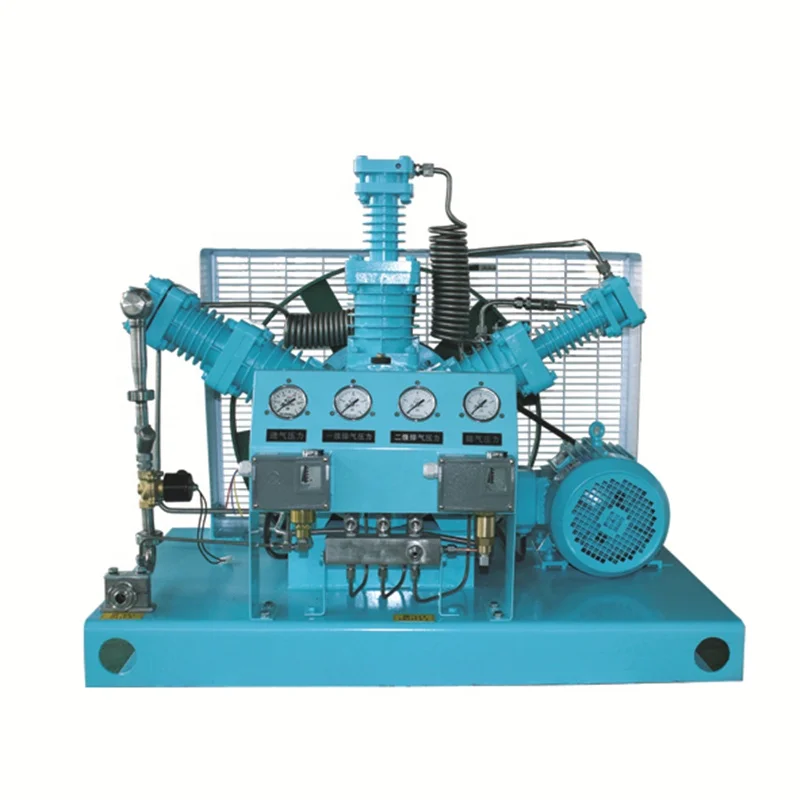

Gas Booster

As the leading Oil-free Compressor/Booster manufacturer in China, Gas Booster is an important product for us.

Our Gas Booster is completely oil-free and does not use any lubricating oil. The cylinder is made of stainless steel with oil-free design. The guide ring, piston ring and piston rod packing are all made of self-lubricating material, with 100% oil-free lubrication. All this assures that oxygen is clean and pollution-free. High temperature resistant grease lubrication is adopted for bearing parts, which will not contact with compression medium, avoid gas pollution during compression process, to ensure gas purity. It was controlled by the microcomputer controller, it has the functions of high exhaust temperature, low intake pressure and high exhaust pressure with alarm shutdown, high automation level, and more reliable operation.

Our Gas Booster’s working speed is very slow, usually 200-400rpm, which is suitable for 24 hours of continuous working conditions.

We can configure data remote display and remote control according to customer’s requirement.

Our Gas Booster can be used in hospital oxygen centers to increase the pressure of oxygen lines in rooms, and to boost oxygen and fill cylinders. It can also be used for industrial acetylene combustion cutting, waste steel cutting in steel works, supporting boiler oxygen combustion, and circulating the steam oxygen in low temperature liquid oxygen tank to the tank for various working conditions.

According to the customer's oxygen usage, Our Gas Booster are divided into 5 types according to the cylinders form:

♣ Level-1 compression, single cylinder

♣ Level-2 compression, double cylinder

♣ Level-3 compression, triplex cylinder

♣ Level-4 compression, four cylinder

♣ Level-5 compression, vertical style

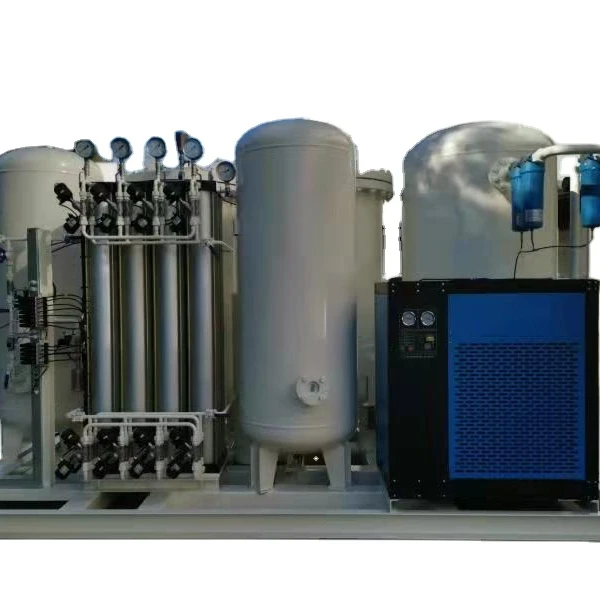

Oil-free low pressure Gas Booster, could be used in industrial boiler combustion support, hospital centralized oxygen supply booster, and other fields. The pressure ranging is from 0.2~3bar to 10bar-15barg.

Oil-free high pressure Gas Booster, could be used for high pressure oxygen bottle filling, so as to facilitate the oxygen storage and transport. According to the customers' demand, the filling pressure is divided into 15mpa, 20mpa, and up to 30mpa. The filling is flow from 1Nm3/h to 300Nm3/h, especially suitable for the filling of PSA oxygen generator. It has characteristics of clean, totally oil-free, simple operation, reliable quality, low speed, and low noise. The Gas Booster could be working in continuous working conditions for a long time, which is the best choice of oxygen compressor.

Gas Booster, according to the cooling way, can be divided into air cooled and water cooled, customers can choose from it according to the actual local situation.